FAQ

The database contains 400 products and 100 users.

The database includes:

- product identification number used to call it

- product barcode,

- product name,

- User identification number,

- user name,

- the unit weight of the product, used to count the quantity,

- entering a fixed tare for a given product,

- lower threshold value (Min),

- upper threshold value (Max),

- the label number that corresponds to the product.

Using the database is greatly facilitated by a handy scanner (barcode reader for PLN 280 !!! ), which allows for quick identification of weighed goods. Calling a product from the database allows you to measure the net, gross, and tare weight, assess the correctness of their weight (Min/OK/Max selection), count pieces, print labels, etc.

If the basic functionality is not sufficient, we offer ETE computer software for a fee, which extends the possibilities of using codes of goods, operators, packaging, and contractors, and also enables archiving of results. The single workstation version of the program (computer + one scale) is at a promotional price (50% cheaper!!!).

The database is installed in all standard BTA, BD, BA, and 4BA series scales as well as ME-01 and ME-11 weighing meters (without any extra charges!!!).

What does the Autozero function do?

When this function is activated, zero indications are automatically maintained when the pan is not loaded or zero indication was obtained as a result of pressing the →T← key.

For balances with →0← key, the function works within 4% of Max.

In other scales - in full range.

What does the Piece Count (Pcs) function do?

The function allows you to count identical details, e.g. tablets or buttons in a weighed portion.

The measurement takes place in two phases:

- phase one - calculation of the weight of a single detail based on a sample of a specific number of pieces: 5, 10, 20, 50, 100, 200 or 500 details,

- second phase - counting the details in the weighed batch.

What does Perc conversion (Perc) do?

This function allows you to read the weight measurement result as a percentage of the reference weight.

What does the Recipe function do?

The function allows for the separate weighing of several ingredients in one vessel with the possibility of reading the total mass value of all components weighed so far. The number of ingredients can be any, but their total weight cannot exceed the weight range.

What does the Thresholds (Thr) function do?

The function allows you to compare the weighing result with two previously programmed values: lower and upper threshold.

If the weighing result is:

- lower than the lower threshold - the scale signals MIN,

- between thresholds - scale signals OK,

- greater than the upper threshold - the scale signals MAX.

An acoustic signal is also generated when thresholds are exceeded.

The result of the comparison can be used to control the dosing devices or the optical indicator through the output connector (optocoupler).

What is the clock/date option (Date)?

The internal clock is in the balance. Activation of the function causes the date and time to be printed next to the measurement result after pressing the transmission key (Print) and when printing out special functions.

The Clock/Date function works both for mass and quantity measurements (piece counting).

The detailed appearance of the printouts is described in the manual of the selected balance.

What does the sum (Total) function do?

The function allows us to calculate the total mass of goods weighed in successive portions (mass greater than the range of the scale). It is possible to print a receipt for each measurement and to print a report after completing a series of measurements.

What does the statistics function (Stat) do?

The function calculates statistical parameters from a series of measurements (max 500 measurements).

Successive measurements are passed (entered into the register) automatically after the load is applied and the scale indication stabilizes. The feature is available on standard scales.

For a series of measurements obtained in this way, the balance calculates:

- n - number of samples

- total - sum of masses of all n samples

- average - average mass as (total)/n

- min - minimum mass in n samples

- max - maximum mass in n samples

- max-min - difference between max and min value

- S - standard deviation

- S% - standard deviation in percent

A diagram of the results is also drawn.

The price includes the installation of the clock in the scale.

Sample statistics and histogram printout:

.jpg)

It is a confirmation that the accuracy of the balance is within the (quite wide) limits set by the standard.

Legalization is performed by the Office of Measures or weighing manufacturers/distributors with special authorizations.

Legalization does not answer the question: how accurate is the scale? He says that this accuracy is sufficient for the indicated applications.

When is legalization needed?

Scales for determining mass are subject to mandatory verification:

- in trade*;

- weight which is the basis for calculating market fees, duties, taxes,

bonuses, discounts, penalties, salaries, compensation, or similar types of fees;

- when applying legal provisions and when issuing opinions in court proceedings by experts and experts

- patient weight in medical practice for monitoring, diagnosis, and treatment;

- in the preparation of prescription drugs in pharmacies;

- during analyzes carried out by medical and pharmaceutical laboratories;

- when packing goods.

Scales do not have to be verified for all applications not listed above:

- technological processes

- for the internal control of goods

- under quality assurance systems

- for home use

* Special legalized scales are required for direct sale.

How long is legalization valid for?

The first legalization of the scale made before 01-01-2019 is valid for the next 3 calendar years without the last month.

The first verification made in 2019 or later is valid for the next 2 calendar years without the last month, e.g. a scale with conformity assessment made from January to December 2019 is valid until November 30, 2021.

Regulation of the Minister of Entrepreneurship and Technology of March 22, 2019 (Journal of Laws of 2019, item 759)

Re-verifications are valid for 25 months starting from the date of verification (the expiration date is determined by the signs affixed to the scale).

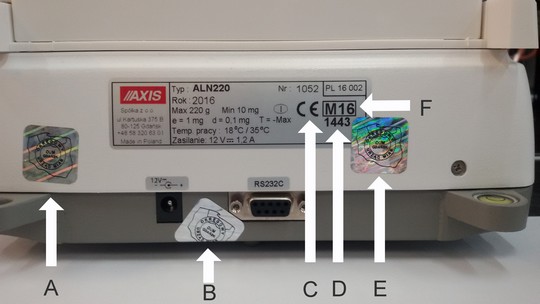

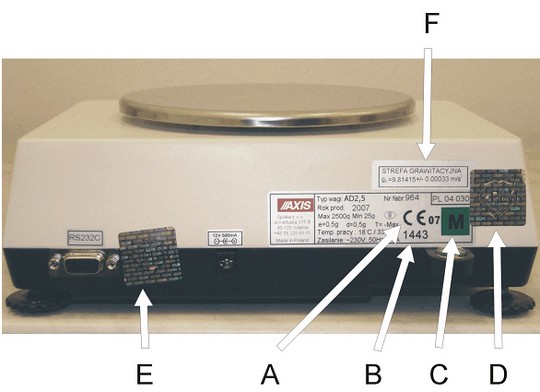

What marking does a legalized scale have?

Current marking:

A - legalization feature of the Office of Measures or AXIS feature

B - legalization feature of the Office of Measures or AXIS feature, securing access to adjustment (balance calibration),

C - the mark of conformity with European Union directives (CE mark, details in the declaration of conformity),

D - number of the notified body performing the conformity assessment (Office of Measures or AXIS),

E - legalization mark of the Office of Measures or AXIS mark

(partly glued on the company plate)

F - metrological designation M and the last two digits of the year of conformity assessment.

Additionally, the following applies:

- an indication of the gravitational zone in which the verification is valid, the gravitational acceleration value and tolerance are given,

- legalization feature imprinted in modeling clay, securing access to balance elements.

Old designation (used until 07/11/2016)

What about legalizing old scales?

The current Act on Measures sets December 31, 2013 as the last possible date for re-verification of scales manufactured before 2004 (ie according to the old regulations). After this date, scales can be legalized, but compliance with the current requirements is checked (according to the Legalizator's indications).

We are here to help if necessary. Download and fill out the form from the link below and send it to m.maliszewski@axis.pl

Calibration is checking the balance with a reliable weight standard.

Calibration answers the question: how accurate is the scale? The result of calibration is the determination of the error and uncertainty of the balance.

The error is the difference between the standard mass value and the scale's indication. Uncertainty defines the scatter limits of the determined measurement error.

A reliable mass standard is a standard checked with traceability, i.e. there must be an uninterrupted chain of references to a national or international standard. In practice, it must be a mass standard with a valid calibration certificate

Calibration is used to assess the condition and suitability of the balance for measurement tasks.

In addition, calibration enables the calculation of error and uncertainty of measurements made with this balance.

What is calibration needed for?

Calibration determines the actual accuracy of a balance, which can be used to assess its usefulness and technical condition.

The direct reason for the use of calibration is the requirements of quality systems such as ISO.

The PN-EN ISO 9001 February 2009 standard says that:

7.6 Where it is necessary to ensure reliable results, measuring equipment should be calibrated and/or checked at specified intervals or before use against measurement standards linked to international or national measurement standards.

Who performs balance calibrations?

Calibration is usually performed by an accredited measurement laboratory. Measurements are performed by qualified laboratory staff according to established procedures in strictly defined conditions (temperature, humidity, pressure, etc.).

However, there are no obstacles to doing it yourself!

Calibration - how is it done?

An indispensable tool for balance calibration is one or several mass standards including values (calibration points) for which calibration will be performed. Usually, they are Min, 50% Max and Max for the calibrated weight.

You need to know the errors and uncertainty of these mass standards (they are written on the calibration certificates).

You also need the value of the scale's reading division.

We perform a series of measurements, noting the scale's indications.

We substitute into the formulas and calculate the error and uncertainty. We do it for each calibration point separately.

I will do this myself!

Calibration - the computer will do it for me!!

A simple download.

Using the program, calibrations are performed separately at each calibration point.

When entering mass standards for a given calibration point, make sure that the standard or the sum of standards coincides with the current calibration point.

The measurement results (we recommend 10 measurements) should be written down from the balance. The transition to the next measurement takes place after pressing the Enter key twice (it works faster than the mouse).

After performing the calibration for all planned calibration points, you can generate a Report in the form of a table. This table can be copied to an Excel sheet and any necessary elements of the calibration certificate can be added there (company lettering, descriptions, signatures, etc.).

GOOD LUCK!

It is a product placed in a single package, the nominal quantity of which (not more than 50 kg or 50 l) cannot be changed without breaking the package.

The rules of conduct for the packaging of goods are set out in the Act of 7 May 2009 on prepackaged goods.

Responsibilities of the packer?

The packer or the person ordering the packing is obliged to:

- notification to the director of the regional office of measures of the fact of packing within 7 days of its commencement,

- proper labeling of the product (name, nominal quantity, company),

- organize an internal check to ensure that the actual quantity of the goods corresponds to the nominal quantity.

Whether the actual quantity corresponds to the nominal quantity is finally determined by an external (official) control carried out using a reference method or another equally effective method. The reference method is a statistical method, described in detail in Annex 2 of the Act.

Therefore, the packer can use any method of measuring the net weight of his goods, but it must be a method that is so reliable that the reference method test will confirm a positive result.

Responsibilities of the signifier?

If the packer or the party ordering the packing applies the e mark to his goods, he has more obligations.

In addition, it must prepare a description of its internal control system (for inspection by inspection authorities), conduct inspections and keep records of internal inspections performed. The storage period for the documentation should be 2 years (or as long as the shelf life of the goods, but not less than one year).

This applies to products with a nominal amount of 5g (5ml) to 10kg (10l).

What must the internal control check?

The internal control checks the average value of the net weight of the goods in the batch. This value should correspond to the net value marked on the product packaging.

But that's not enough.

The batch cannot contain items whose net weight is clearly too small (underweight greater than twice the permissible error marked as T1). Slightly underweight pieces (underweight greater than T1 but less than twice T1) must also not be more than 2% in the lot.

In addition, internal inspections taking place directly on the production line must quickly catch failures in the production process, so they must take place at least once an hour.

What is the reference method?

The method strictly defines the requirements for the method of carrying out measurements of a batch of goods and their results. It determines the number of samples of goods taken from the batch, the formulas for calculating the average value and the permissible error of the net mass (T1) and the qualifying values for the measurement results.

Two types of control are described:

- destructive control - measurement of the net weight of a sample consisting of 20 pieces (packages are destroyed when opened),

- non-destructive inspection - two-stage inspection, two samples are taken from a batch of goods, the amount taken for samples depends on the number of batches of goods, if the results of the first sample are unambiguous, the second sample is not needed.

The permissible number of defective items depends on the size of the batch and is given in the tables. The average value must correspond to the nominal value, taking into account a slight deviation resulting from the statistical method of calculating the average.

A detailed description of the reference method is contained in Annex 2 to the Act on Packaged Goods.

Weight requirements

For internal control of packaged goods, scales with accuracy class III or better, which must be verified, should be used.

The condition that the scale accuracy cannot be worse than 20% of the admissible net mass error (T1) results in limitations as to the accuracy of the scales used, depending on the net mass of the packaged goods.

This is illustrated by the following table

What about the packaging tare?

Direct measurement of the net weight is only possible with the destructive method. There, the packaging is opened and emptied.

If we have a closed package that we do not want to open, we calculate the net weight by subtracting the tare weight from the gross weight. Two methods are possible here:

Method 1

Before filling each package, measure its individual tare, then measure the filled package and subtract its individual tare.

This method is used in particular for glass packaging with large differences in weight.

Method 2

The average tare is determined from a sample of 10 packs. The weight of the filled packages is then measured and the average tare is subtracted.

This method can be used provided that the tare determination error does not exceed 1/4 of the value of the allowable error in determining the net mass (0.25*T1). It is necessary to take into account the error of determining the tare caused by the dispersion of tares of individual packages and the accuracy of the scale used.

In practice, this method can be used for plastic and paper packaging, which usually have small differences in weight.

A computer program for controlling packaged goods

Go to product

Nie. Legalizacja wagosuszarek nie jest ujęta w przepisach i co za tym idzie nie jest wymagana.

Podstawa prawna: Rozporządzenie Ministra Gospodarki z dnia 7 stycznia 2008 r. w sprawie prawnej kontroli metrologicznej przyrządów pomiarowych

Co z wzorcowaniem wagosuszarek?

Możliwe jest wzorcowanie wagosuszarki w zakresie wskazań masy. Jest to istotne, gdyż na wskazaniach masy oparte są wyniki pomiaru wilgotności, ale to nie jest dokładnie to o co chodzi. Wzorcowanie takie daje formalne świadectwo wzorcowania wagosuszarki i pozwala wnioskować o sprawności urządzenia.

Wzorcowania w zakresie wskazań wilgotności jak dotąd żadne znane nam laboratorium akredutowane nie robi, nie mamy zatem komu tego zlecać. Sami wykonujemy protokóły z pomiarów dla konkretnej wagosuszarki i rodzaju substancji określając wynik wilgotności i jego powtarzalność.

Dobór parametrów suszenia do badanego materiału?

Dobór właściwej temperatury i czasu suszenia jest kluczowy z punktu widzenia dokładności pomiaru wilgotności. Parametry suszenia dobrane są właściwie, jeżeli zapewniają powtarzalność wyników na zadawalającym poziomie, zwykle jest to 0,1 - 1%. Dobór parametrów odbywa się w 3 krokach:

Krok 1: Temperatura suszenia jest związana z fizyko-chemicznymi właściwościami materiału próbki. Wyznacza się ją w wyniku kilku prób przeprowadzonych w kilku kolejnych temperaturach, np. w odstępach co 10°C . Właściwa temperatura to największa wartość, dla której próbka przez kilka minut nie zmienia koloru i zapachu. Zmiana koloru lub zapachu świadczy o rozpoczęciu procesu utleniania próbki, który powoduje zmianę właściwości próbki, co zwykle ma wpływ na dokładność pomiaru.

Krok 2: Masa użytej próbki powinna być na tyle duża, aby wykorzystać całą powierzchnię szalki, jednakże im cieńsza jest warstwa materiału próbki tym lepiej przebiega proces suszenia. Należy zadbać o to, aby wierzchnia i spodnia warstwa materiału suszyły się równocześnie. Jeżeli materiał pokrywa się skorupką i część wilgoci zostaje uwięziona w materiale, należy materiał rozdrobnić lub obniżyć temperaturę suszenia. Do materiałów płynnych korzystne jest zastosowanie sączków, co przyśpiesza suszenie.

Krok 3: Do przyjętej masy próbki należy dobrać czas suszenia. W tym celu należy ustawić w wagosuszarce możliwie długi czas suszenia i obserwować przebieg procesu suszenia. Minimalny czas suszenia to ten, po którym próbka nie zmieni już swojej masy o więcej niż dopuszczany przez badającego błąd pomiaru. Właściwy czas suszenia to wyznaczony minimalny czas suszenia wzięty z zapasem. Procentowa wartość tego zapasu musi przekraczać rozrzut nakładanej masy próbki, gdyż potrzebny do wysuszenia tanie repliki zegarków próbki czas jest proporcjonalny do masy próbki.

Po przeprowadzeniu kilku pomiarów z wyznaczonymi parametrami suszenia i upewnieniu się, że powtarzalność wyników jest zadowalająca można przystąpić do optymalizacji czasu pomiaru wybierając korzystniejszy Profil suszenia i stosując Tryb pomiaru Skrócony. Oczywiście należy skontrolować, czy powtarzalność wyników się nie pogorszyła. Przykładowe wartości dla najczęściej spotykanych materiałów podane zostały w dodatku do instrukcji obsługi wagosuszarki.

Kiedy stosować filtry (sączki)?

W przypadku suszenia próbek ciekłych, past lub substancji, które mogą się roztopić albo uwolnić płyn, korzystne jest stosowanie filtrów (sączków) z papieru lub włókna szklanego.

Filtry zapewniają rozkład cieczy na większej powierzchni, co przyśpiesza suszenie. W przypadku ciał stałych przykrycie filtrem chroni ich powierzchnię przez utlenianiem się (osmaleniem).

Jak sprawdzić dokładność pomiaru wagosuszarki?

W celu sprawdzenia dokładności ważenia wagosuszarki należy przełączyć wagosuszarkę na zwykłe ważenie i nałożyć na szalkę przedmiot o dokładnie znanej masie. Najlepiej jeśli jest to odważnik kalibracyjny F2 (OIML) o masie równej zakresowi pomiarowemu wagosuszarki, ale może to być dowolny przedmiot, którego masa jest nam dokładnie znana.

Klasyczna metoda sprawdzenia dokładności wyznaczania wilgotności wymaga użycia substancji wzorcowej – winianu disodowego (di-Sodium tartrate dihydrate C4H4Na2O6*H2O). Do sprawdzenia należy użyć próbki o masie 5g ustawiając: tryb skrócony, metodę wyliczeń: m0-m/m0*100% , temperaturę 150oC, czas próbkowania 10s., ilość kwalifikującą 4 i czas suszenia 00:15:00s. Uzyskany wynik powinien mieścić się w granicach 15,61 – 15,71% (dokładna wartość jest podana na opakowaniu substancji).

Prostszą metodą jest użycie sączka i wody destylowanej (woda z kranu jest też wystarczająca). Przy ustawieniach wagosuszarki jak wyżej pomiar wilgotności ok. 1cm3 wody musi się skończyć wynikiem paradoksalnym tj. bliskim 100%, ale jest to wartość prawidłowa, a powtarzając pomiar kilkukrotnie można ocenić powtarzalność i dokładność wagosuszarki.